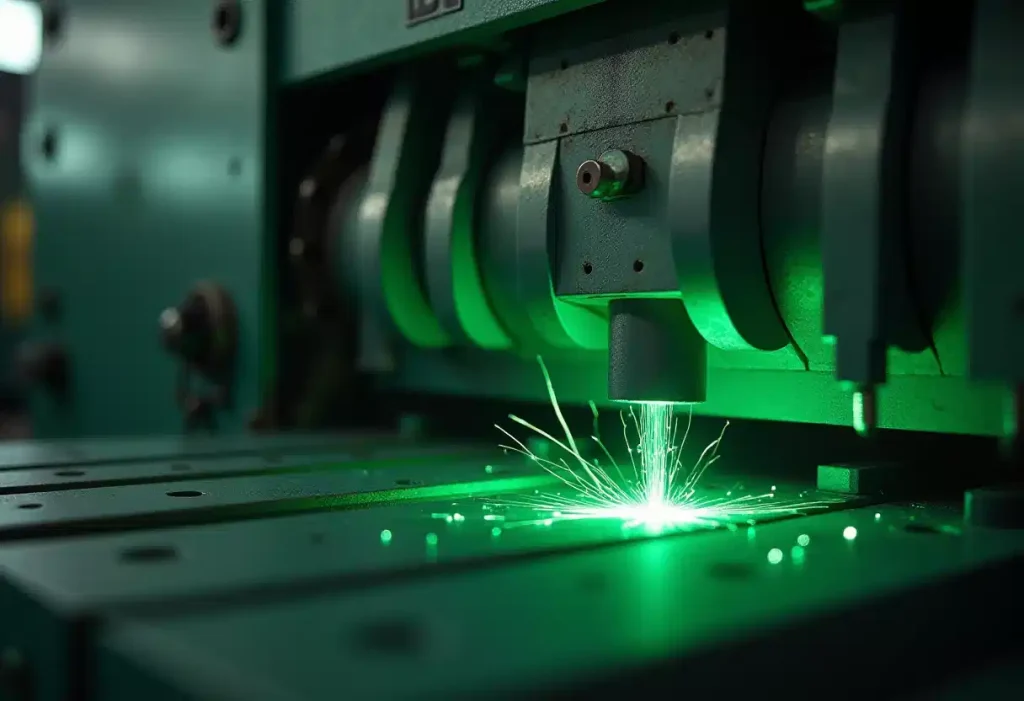

Just launched is the new Induction Bending Cell from metal forming specialist Inductaflex. The machine is capable of induction bending pipes and other shaped sections at previously un-heard of speed and efficiency.

Bend speeds

The machine typically bends at speeds up to 400 mm per minute, which is fast for this type of hot bending process. Thanks to its automatic loading function, it can process 250 to 300 standard 3D bends daily. Additionally, the machine forms all pipe grades, including pipeline specifications, stainless steel, alloys, cast nickel pipes, and internally weld-clad pipes.

PLC operation

The system operates intelligently and automates much of the process, reducing many complexities associated with induction bending.

Multi shapes

The machine processes various shapes, including square hollow sections and custom-formed profiles.

3-dimensional bends

The machine can also be fitted with our 3-dimensional bending adaptor. This servo electrically controlled device allows sections to be bent in multi axes for various complicated piping requirements.

Range

Our bending cell range starts at 1” – 6” and extends up to 20” pipe.

Should you have a requirement for an induction bending cell, please call or e-mail us with your section size, type and radius requirements.

Get in touch with us today to discuss your specific induction bending requirements and discover how our advanced bending solutions can help your project succeed!