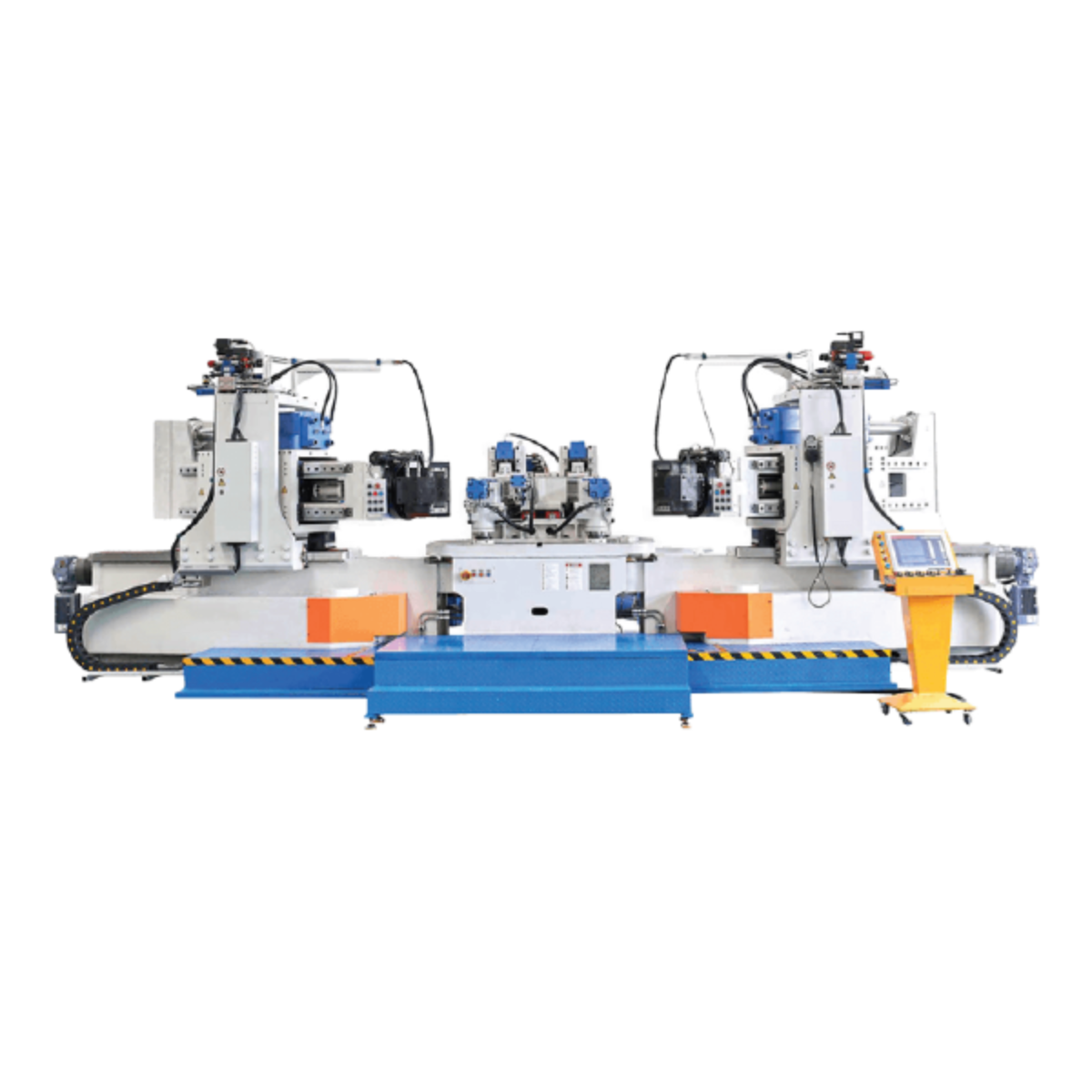

THE WORLD’S MOST CAPABLE ALUMINUM BENDING & FORMING SYSTEMS

Inductaflex delivers the world’s most advanced aluminum bending & forming machines, engineered for precision, reliability, and efficiency. Trusted by leading names in automotive, construction, architecture, and manufacturing, our systems help global innovators achieve flawless results at scale. With dedicated operations in the US, UK, and Vietnam, Inductaflex provides world-class service and support across continents- empowering businesses everywhere to bend smarter, faster, and better.

Trusted by world leading brands

Trusted by world leading brands

Which bending machine is best for your needs?

WHY CHOOSE INDUCTAFLEX

Stretch Forming & Roller Bending

Receive expert recommendations for your specific profile bending needs.

Available in both standard and high-volume models.

Reduce Waste & Save Energy

Intelligent machines capable of re-bending parts to reduce material waste.

Servo-electric technology delivers up to 70% energy savings.

Comprehensive & Tailored Solutions

Tailored solutions designed to optimize OPEX and CAPEX.

Seamlessly integrates with existing production systems.

Provides fully or semi-automated bending cells with complete end-to-end processing.

We Trust World-Leading Brands In Our Machines

Siemens

Allen Bradley

Yaskawa

EXCLUSIVE SERVICES WITH LIMITED OFFERS

MAINTENANCE

Software updates

Spare parts supply

Performance optimization

TRAINING

On-site Customer Training

Advanced Technical Training

Video Training

TECHNICAL SUPPORTS

Technical support for troubleshooting & services.

Spare parts guide for repairs and adjustments.

INSTALLATION & SET UP

On-site machine installation with guidance.

On-site Supervision & Consultancy.

TOOLING DESIGN & SUPPLY

Custom Tool Design, Plans.

Custom Manufacturing Tools.

TECHNICAL CONSULTATION

Expert testing and evaluation for complex cases.

On-site machine customization and solutions for specific requirements.

MEDIA

New 2025 Catalogue released with 3 new machines.

GET YOUR PROJECT STARTED WITH A FREE QUOTE

Our Sales & Engineering team helps you find the right machines for your needs.