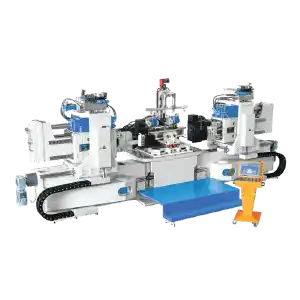

STRETCH FORMING MACHINE

- Precision Control

- Robust Clamping System

- Advanced PLC

- Easy Maintenance

STRETCH FORMING MACHINE

- The World’s most desired new entrant to the market

- Bend from hundreds to hundreds of thousands of parts per year.

- World leading stretch bending control software to produce the best formed parts.

- Used by most of the World’s leading automotive brands

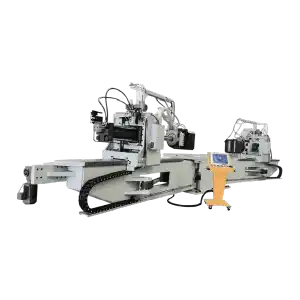

Specs

- Robot loading of parts

- Robot saw function to cut the lead material to length

- Additional safety scanners

- Integrate and adapt with existing system or/and machining cell

- Support tables for large parts

- Z axis for asymmetric profiles

- Profile design consultation

- Tool design

- Bespoke functions

Optional extras

- Robot loading of parts

- Robot saw function to cut the lead material to length

- Complete bend cell set up

- Additional safety scanners

- Link to an existing machining cell (Integrate and adapt with existing system or/and machining cell)

- Support tables for large parts

- Z axis for asymmetric profiles

Besides, We are capable to consult more bending solution, tools and add more functions to software as per requirements

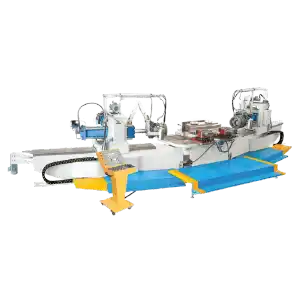

Dimension

Installation and commissioning

The machine should be connected to a 480V, 3-phase, 60Hz power supply via a 32A wall-mounted isolator. Additionally, a compressed air supply of 3 to 5 bar is required.

We highly recommend the machine installed and commissioned under consultancy and supervision of Inductaflex engineers. We offer installation & commissioning , maintenance service to secure specification and operation of machines.

Shipping

Warranty

The warranty period for goods is within 3 years from the date of BL/AWB for any broken, damages, defects be caused to the Goods by quality of Goods and for reason attributable to the Seller.

In case the Goods need to be repaired / replaced within the warranty period, the execution time shall be the minimum reasonable required time from the Buyer and Seller’s agreed date.

The Seller shall be relieved of its obligations under this Warranty to the extent that:

– The Buyer has modified the machines. The damage to the Goods has occurred during transit, or is due to improper storage, unloading, handling or operation by the Buyer

– The Buyer has failed to handle, install, operate and maintain the Goods strictly in accordance with the instruction manual of Seller.

– Wear and Tear parts are excluded from warranty.

In the case of a turnkey project, warranty will commence once the installation is completed.

EXCLUSIVE SERVICES WITH LIMITED OFFERS

MAINTENANCE

2. Spare parts supply

3. Performance optimization

TRAINING

2. Advanced Technical Training &

3. Video Training

TECHNICAL SUPPORTS

2. Spare guide for repairs and adjustment.

INSTALLATION & SET UP

2. On-site Supervision & Consultancy.

TOOLING DESIGN & SUPPLY

2. Tool Manufacturing.

TECHNICAL CONSULTATION

2. On-site machine customization and solutions for specific requirements.

EXAMPLE BENDS

Stretch Former RANGE

| 2D 200kN-4500 | 2D 350kN-5200 | 2D 550kN-6500 | 2D 1200kN-6500 | |

|

|

|

|

|

| Stretching Power | 200kN | 350kN | 550kN | 1200kN |

| Max Distance between Jaws | 4500mm | 5200mm | 6500mm | 6500mm |

| Mould Platform Height | 925mm | 970mm | 980mm | 1050mm |

| Mould Platform Dimensions | 1830 × 1270mm | 2050 × 1280mm | 2360 × 1285mm | 2500 × 1350mm |

| Stretch Cylinder Swing Angle | ±30° | ±30° | ±30° | ±30° |

| Swing Arm Angle | 10° Forward, 90° Backward | 10° Forward, 90° Backward | 10° Forward, 90° Backward | 10° Forward, 90° Backward |

| Swing Arm Precision | ±0.1° | ±0.1° | ±0.1° | ±0.1° |

| Servo Power | 31kW | 37kW | 43kW | 70kW |

| Weight | 12T | 16.1T | 19T | 35T |

Machine in use

FAQs

Common Questions About STRETCH FORMING MACHINE. Contact us with any questions that you may have, or review some of the commonly asked questions that our sales team receives below:

What Is Stretch Bending and How Is It Used for Car Bumper Beams?

Stretch bending is a precision metal forming process where a bumper beam profile is simultaneously stretched and bent over a die. This ensures minimal springback and consistent curvature—ideal for automotive crash components requiring high dimensional accuracy.

Why Choose Stretch Bending for Automotive Bumper Manufacturing?

It allows the beam to be formed in a single step with tight radius control and excellent repeatability. This eliminates the need for costly, multi-step die-press tooling and reduces material waste, while maintaining the crashworthiness and structural integrity of the beam.

What Materials Can Be Stretch Bent for Bumper Beam Applications?

Inductaflex machines can process a wide range of materials commonly used in bumper production, including high-strength aluminium alloys (like 6000 and 7000 series), boron steel, and advanced high-strength steels (AHSS).

What Types of Bumper Beam Profiles Can Be Formed with Stretch Bending?

We can accommodate complex closed or open sections, hat profiles, and custom extrusions used in passenger car and commercial vehicle bumper systems. Our machines are engineered to handle asymmetric or varying wall-thickness designs as well.

What Tolerances Can Be Achieved in Stretch Bending Bumper Beams?

Inductaflex machines can maintain tolerances within ±0.5 mm on bend radii and arc lengths, depending on the profile and material, meeting strict automotive industry standards for fit and finish.

Stretch Bending vs. Press Bending: Which Is Better for Bumper Beams?

Stretch bending offers faster setup, lower tooling costs, and superior part consistency. Unlike press bending, which can introduce local thinning or wrinkling, stretch bending maintains uniform cross-section and structural integrity throughout the profile.

Can Inductaflex Machines Support High-Volume Bumper Beam Production?

Yes. Our stretch bending machines are designed for high-volume, repeatable production, with features such as automated loading/unloading, fast cycle times, and integration into robotic production lines for full automation.

Do You Provide Custom Tooling for Bumper Beam Stretch Bending?

Absolutely. We work with OEMs and Tier 1 suppliers to design and manufacture bespoke stretch bending tooling tailored to each bumper profile and material, ensuring optimal forming results and long tool life.

Is Heating Required During the Stretch Bending Process?

For some high-strength materials or tight radii, controlled heating may be applied to reduce cracking risk and improve formability. However, most bumper beams are stretch bent cold using our precision-controlled machines without need for preheating.

Do You Offer Bumper Beam Prototyping and Pre-Production Support?

Yes. Inductaflex offers full prototyping and development support, including trial bending, CAD simulation, and small-batch production to help accelerate design validation and reduce time to market.

What Kind of After-Sales Support Comes with a Stretch Bending Machine?

We provide full technical support, including commissioning, training, preventive maintenance, and remote diagnostics. Our service network ensures rapid response for spare parts and engineering assistance globally.

What Makes Inductaflex Stretch Bending Machines Unique in the Automotive Industry?

Our machines are modular, fast to set up, and can be tailored to unique bumper profiles. Combined with our automotive expertise and tooling solutions, we offer a highly responsive and cost-effective forming solution that meets demanding OEM standards.

GET YOUR PROJECT STARTED WITH A FREE QUOTE

Our Sales & Engineering team helps you find the right machines for your needs.