Aluminum continues to be a reliable material for modern construction. It resists corrosion, has low weight, and can be formed into various shapes. These traits make it practical for curved window frames and custom openings.

6063-T5 is often chosen for architectural profiles because of its surface finish and ease of extrusion. It bends well with the proper setup. 6061-T6, while stronger, needs to be softened in many cases before shaping to avoid cracking during the bend.

When manufacturers select the right alloy and temper, the material bends without distorting or losing strength.

What Makes Aluminum the Architect’s Favorite Metal?

Why Aluminum Works in Architecture

Aluminum continues to be a reliable material for modern construction. It resists corrosion, has low weight, and can be formed into various shapes. These traits make it practical for curved window frames and custom openings.

Choosing the Right Alloy

6063-T5 is often chosen for architectural profiles because of its surface finish and ease of extrusion. It bends well with the proper setup. 6061-T6, while stronger, needs to be softened in many cases before shaping to avoid cracking during the bend.

Formability Depends on Temper

When manufacturers select the right alloy and temper, the material bends without distorting or losing strength.

From Blueprints to Beautiful Bends

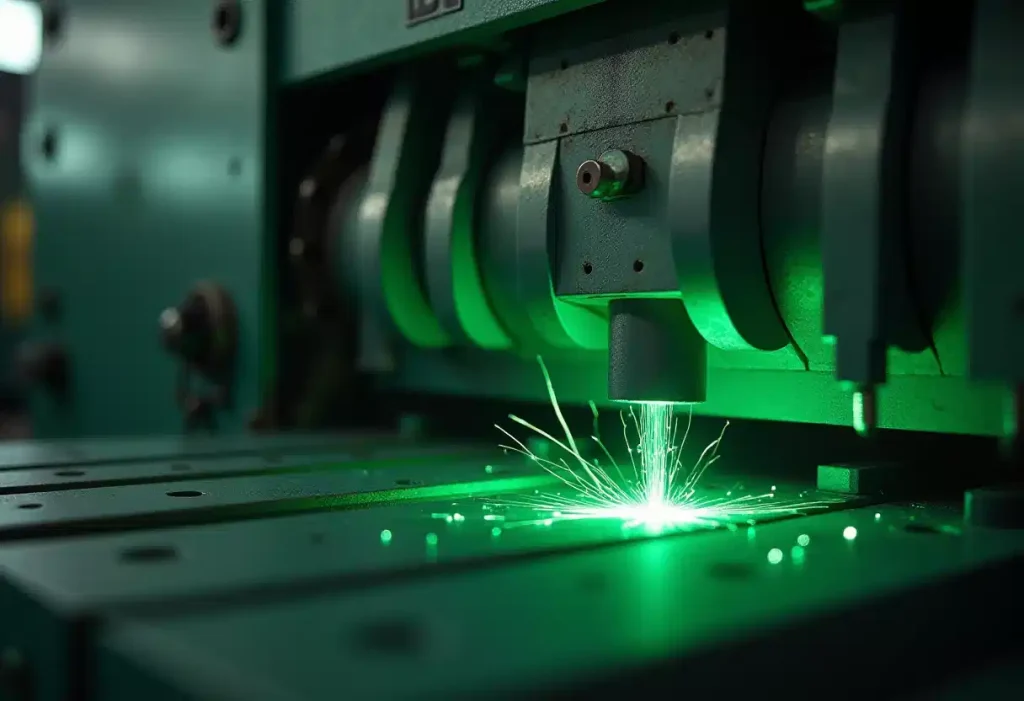

Bending Methods Used in Window Frame Fabrication

Once the design is final, the bending process begins. The type of profile and radius needed will determine which method the fabricator uses.

- Roll bending works well for long, wide curves.

- Stretch forming suits projects that need high accuracy along sealing edges and glass grooves.

- Rotary draw bending is used for more compact profiles or tighter arcs.

Cold Bending and Material Suitability

In most cases, aluminum is bent without applying heat. Softer alloys, generous radii, and good tooling help reduce the risk of cracking or surface defects.

Windows That Wow: Where Curves Make a Difference

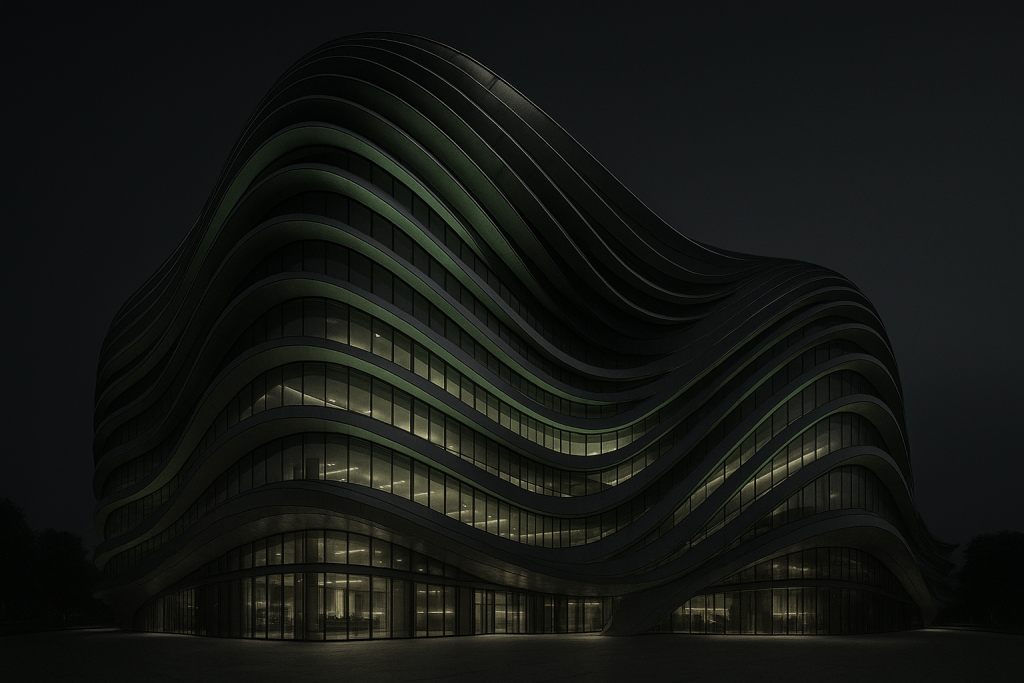

Curved Windows as Architectural Features

Curved frames serve both structural and visual functions. These windows stand out as architectural features in high-end homes, public buildings, and commercial spaces.

Where You’ll See Them Most

Some common uses include:

- Arch-topped windows above entry doors

- Round or oval windows in stairwells

- Curved sliding doors in open-plan layouts

- Multi-section curtain walls shaped to follow a curve

Why They’re Gaining Popularity

More builders are using curved windows in their designs because these shapes introduce motion and softness into otherwise flat façades.

Custom Without Compromise

Precision is Key in Curved Frames

Curved frames must meet precise design requirements. The profiles need to retain their shape, allow proper glass seating, and stay aligned with gaskets and seal points.

How Fabricators Maintain Accuracy

To meet those requirements, fabricators use:

- Controlled bending to maintain consistent arc shape

- Support tools to prevent deformation

- Surface protection techniques during forming

Thermal Breaks and Bending Order

Some profiles are bent before thermal break systems are inserted. Others are shaped after the break has been added, using dies that protect both the frame and insulation. Both methods are used to produce accurate results and preserve structural function.

Sustainability in Every Curve

Aluminum’s Recyclability

Aluminum offers a long service life and can be recycled many times without losing strength. Using recycled material also lowers the overall environmental impact of a project.

Performance and Energy Savings

Curved aluminum frames can be used with insulated glass units, weather sealing, and other high-performance systems. These features help meet building standards for energy use while still giving designers freedom with shape and layout.

The Future is Frameless… and Fluid

Curves in Contemporary Design

Designers are using more curved and organic forms in buildings. These shapes are found in homes, hotels, spas, and spaces that aim to feel more open and calm.

Hidden Support Systems

Even when a design hides its frame behind glass, structural support is still required. Concealed aluminum carries loads, supports anchoring systems, and keeps the glazing in place.

Why Aluminum Still Leads

Because aluminum forms predictable curves and holds its shape well, it’s widely used in both visible and concealed parts of these systems.

Conclusion

Curved window frames made from aluminum change how buildings look and feel. These shapes bring more light, guide movement, and introduce softness to flat surfaces.

When fabricators use the correct alloy and forming method, the resulting frame will fit glass tightly, keep its shape, and stay weather-tight. Curves are now part of regular architectural planning, not just custom features.

Aluminum continues to support these changes. Its ability to bend, resist damage, and match tight tolerances makes it a material of choice in curved construction.

Inductaflex machines help manufacturers produce accurate, repeatable curves in aluminum frames, built for complex shapes, designed to perform.