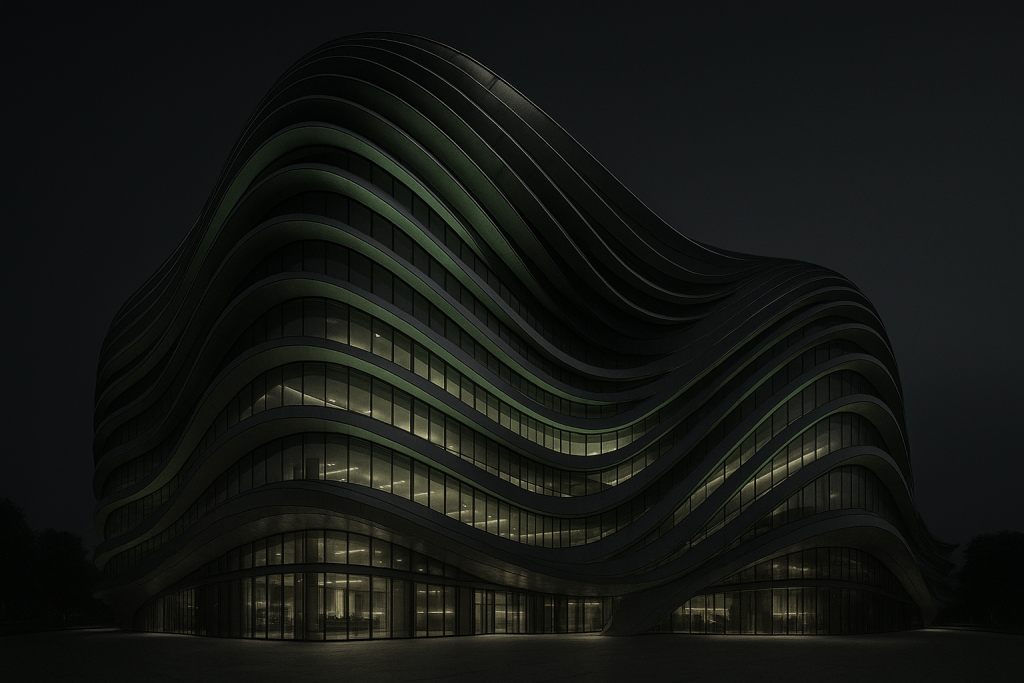

Where Form Meets Function on Every Floor

Curved railings do more than prevent falls. They influence both the appearance and performance of a space. Builders and architects often select custom-bent aluminum railings because these offer strong safety features along with a clean, modern look.

Curves That Keep You Safe

Why Designers Use Curves Instead of Straight Lines

Curved railings improve grip comfort, soften transitions, and support clear sightlines. Architects often choose them for open-plan spaces or elevated walkways. Fewer joints help keep the structure consistent and reduce visual clutter.

Safety still comes first. Every railing must follow local building codes for handrail size, height, spacing, and load-bearing performance—regardless of its shape.

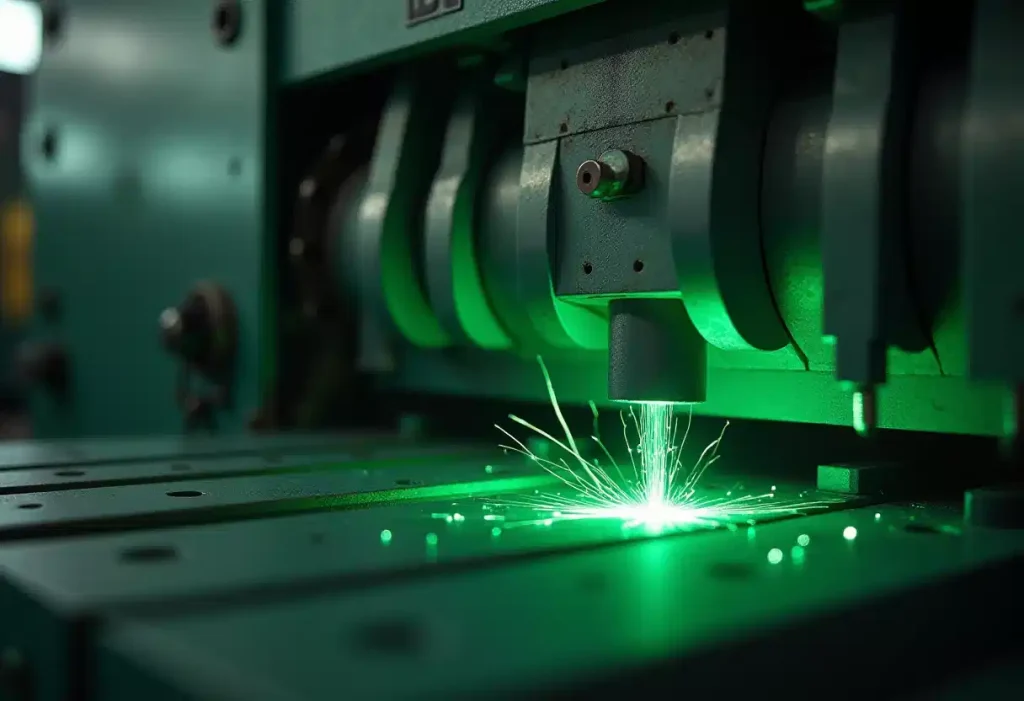

The Bending Behind the Beauty

How Smooth, Strong Arcs Are Formed

Fabricators shape curves using rotary draw bending, roll bending, or CNC profile bending. The method depends on the thickness of the material, the size of the profile, and the desired bend radius.

The term for shaping railing profiles this way is roll bending, not roll forming. Roll forming is used to shape continuous metal sheets, which makes it unsuitable for curved railing production. Bending machines apply consistent force across the profile to form tight, accurate curves without damaging the surface.

From Homes to Hotels: Where You’ll Spot Them

Common Applications for Curved Aluminum Railings

Curved aluminum railings appear in several types of buildings where both appearance and function matter:

- Staircases in upscale homes and hotels

- Balconies with frameless glass in apartment towers

- Access ramps in public buildings

- Rooftop walkways and pool areas that require safety railings

These curved features help define movement and improve the use of space. In each case, local codes still govern how railings are built and installed.

The Material Advantage

Why Aluminum Performs Well in Railings

Aluminum is lightweight and resists corrosion. This makes it suitable for both indoor and outdoor railings, including in coastal areas. Alloys like 6063-T5 and 6061-O are common choices in architectural bending because they provide a workable balance between formability and strength.

It also finishes well. Powder coating, anodizing, and brushing all help match the metal to the project’s color scheme or texture. When strength is critical, builders can select thicker walls or reinforced sections to meet higher load demands.

Customization Without Compromise

Matching Bends to the Project and the Standards

Every project site has unique measurements and layouts. To match this, fabricators adjust profile sizes, bend radii, and mounting methods based on the actual rise, run, and structural layout of the stairs or walkway.

This approach keeps handrail height consistent and fits profiles to the exact geometry. Most bending takes place before thermal break strips are installed to avoid damaging internal components.

Code compliance depends on several factors: profile strength, anchoring, spacing, and grip size. All of these are reviewed during planning to make sure the final result passes inspection.

Clean Lines, Cleaner Footprint

Aluminum’s Recyclability and Durability

Aluminum can be recycled repeatedly without losing its core properties. Using recycled aluminum also reduces the energy footprint of the build. Once installed, aluminum needs less upkeep than steel or wood, which helps keep long-term maintenance low.

Curved rails made in continuous sections use fewer joints and connections. This can shorten install time and reduce the number of parts required. While curved forms don’t always use less raw material, they do help reduce complexity and improve durability.

Conclusion

Grace in Every Grip

Custom-bent aluminum railings offer more than support. They define how a space looks and moves. Their strength comes from careful material selection and precise bending. Their appeal comes from smooth lines that follow the architecture, not fight it.

When done right, curved railings meet code, reduce clutter, and stand up to daily use, either indoors or out. They don’t just add safety. They become part of the design.

Inductaflex bending machines help make this possible, delivering accuracy, repeatability, and clean results for every railing project.