The Curves You Walk Under Every Day

Curved canopies and arched footbridges are easy to overlook, but they rely on thoughtful design and material choice. These shapes are made possible by aluminum and the bending processes used to form it. The result is infrastructure that’s both durable and visually appealing.

Why Aluminum is the Backbone of Modern Public Design

Light, Strong, and Built to Brave the Elements

Aluminum holds up well in outdoor conditions. Its surface naturally forms a protective layer that slows corrosion. It’s light enough to move and install with ease, but still strong enough to support structural loads. These properties help reduce construction time and simplify logistics.

Aluminum doesn’t rust, but it can still corrode in harsh settings such as coastal areas or industrial zones. Protective finishes like anodizing or powder coating are often used to prevent this and extend the lifespan of the material.

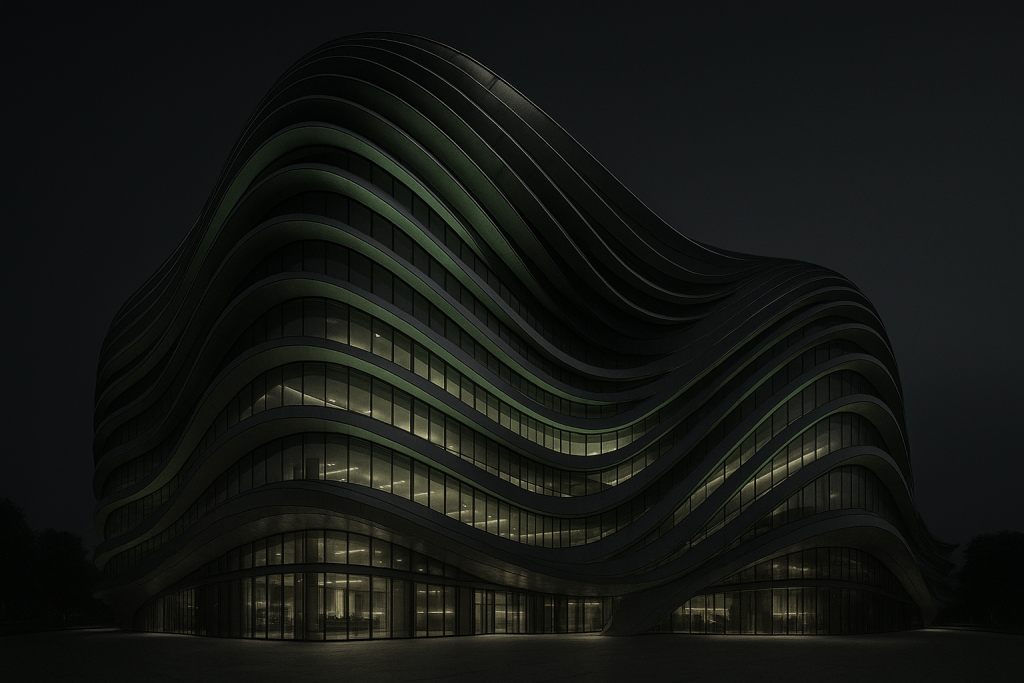

From Shelter to Statement

Curved aluminum profiles add both structure and visual clarity to everyday spaces.

- Curved beams in bus shelters create strong, stable frameworks.

- Arched footbridges use shaped profiles to support weight while keeping a low profile.

- Covered walkways use bent sections to give shade and weather protection without bulky supports.

These elements often include finishes that improve durability and help the structure blend with its surroundings.

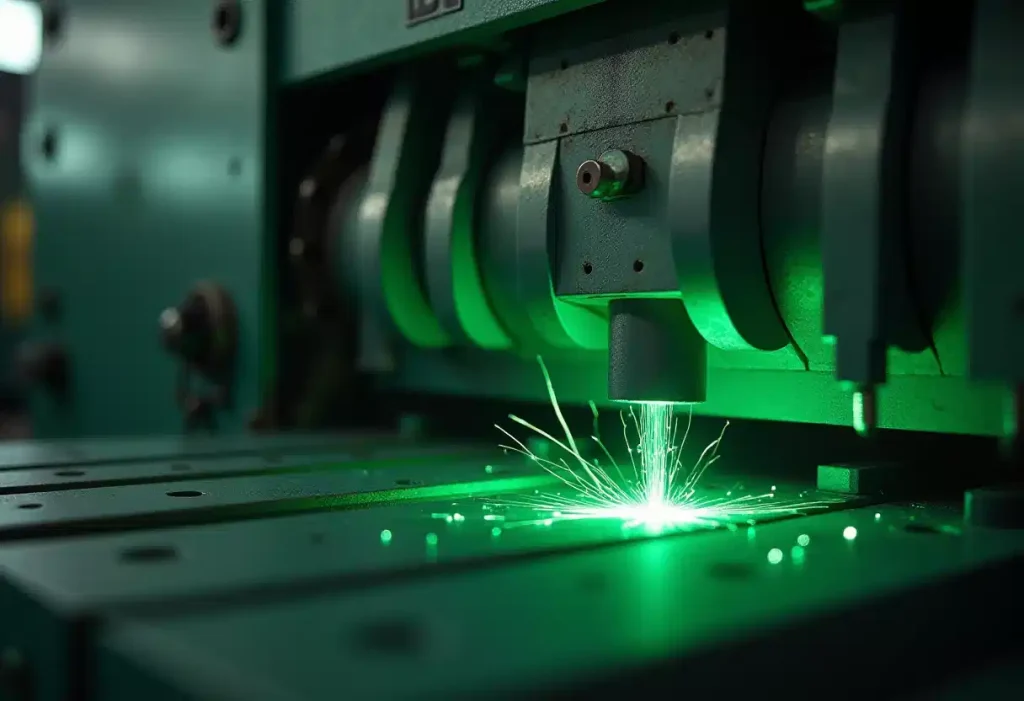

Behind the Bend: How These Profiles Are Formed

Different tools and methods are used to create the curved forms seen in public infrastructure.

CNC roll bending is used for large, smooth curves in structural profiles. Stretch forming is preferred when tighter bends or cleaner surface finishes are needed. Mandrel bending works well for tubes with thin walls, preventing them from collapsing or wrinkling during the process. 3D freeform bending creates compound curves, although this method is limited to certain types of profiles and applications.

Each technique is chosen based on the shape, radius, and material thickness needed for the project.

Built to Last and Made to Move

How Aluminum Keeps Cities Flexible and Resilient

Aluminum works well in projects that need flexibility and speed.

Modular shelters, temporary bridges, and emergency structures all benefit from the material’s light weight and easy handling. This helps shorten installation time and reduces labor. With the right finish, aluminum also requires less maintenance than many other materials.

Designers still need to account for environmental exposure, especially when working in aggressive or marine conditions. Planning for these challenges early helps maintain the structure’s performance over time.

Where Form Improves Function

Curved structures support practical goals while offering clean, modern aesthetics.

Arches can spread out weight and reduce the number of supports needed. Rounded roofs allow water to drain more easily, helping to prevent leaks and pooling. Smooth bends help lower stress in transition points, making the overall structure more durable.

These design choices have proven effective in shelters, bridges, and walkways around the world.

Sustainable Cities Start with Smart Materials

Aluminum is widely recycled in construction and manufacturing. When processed properly, it keeps most of its original strength. Clean sorting and alloy control help maintain this performance in reuse.

Recycling aluminum helps reduce construction waste and lower energy use across the structure’s lifespan. Choosing aluminum means fewer replacements, less maintenance, and less pressure on supply chains.

Conclusion

Aluminum bends are part of the design choices that make cities easier to use and navigate. These forms support everything from pedestrian safety to shelter during bad weather. They don’t just look good. They work hard.

As city needs grow, aluminum offers a reliable material for long-term use. Its performance, ease of handling, and wide availability make it a strong choice for modern infrastructure. When paired with the right bending technique, it helps engineers and architects create spaces that work and last.

Looking to shape your next public project? Inductaflex machines handle complex bends with precision and reliability.