That Sleek Curve Above You? It’s Aluminum at Work

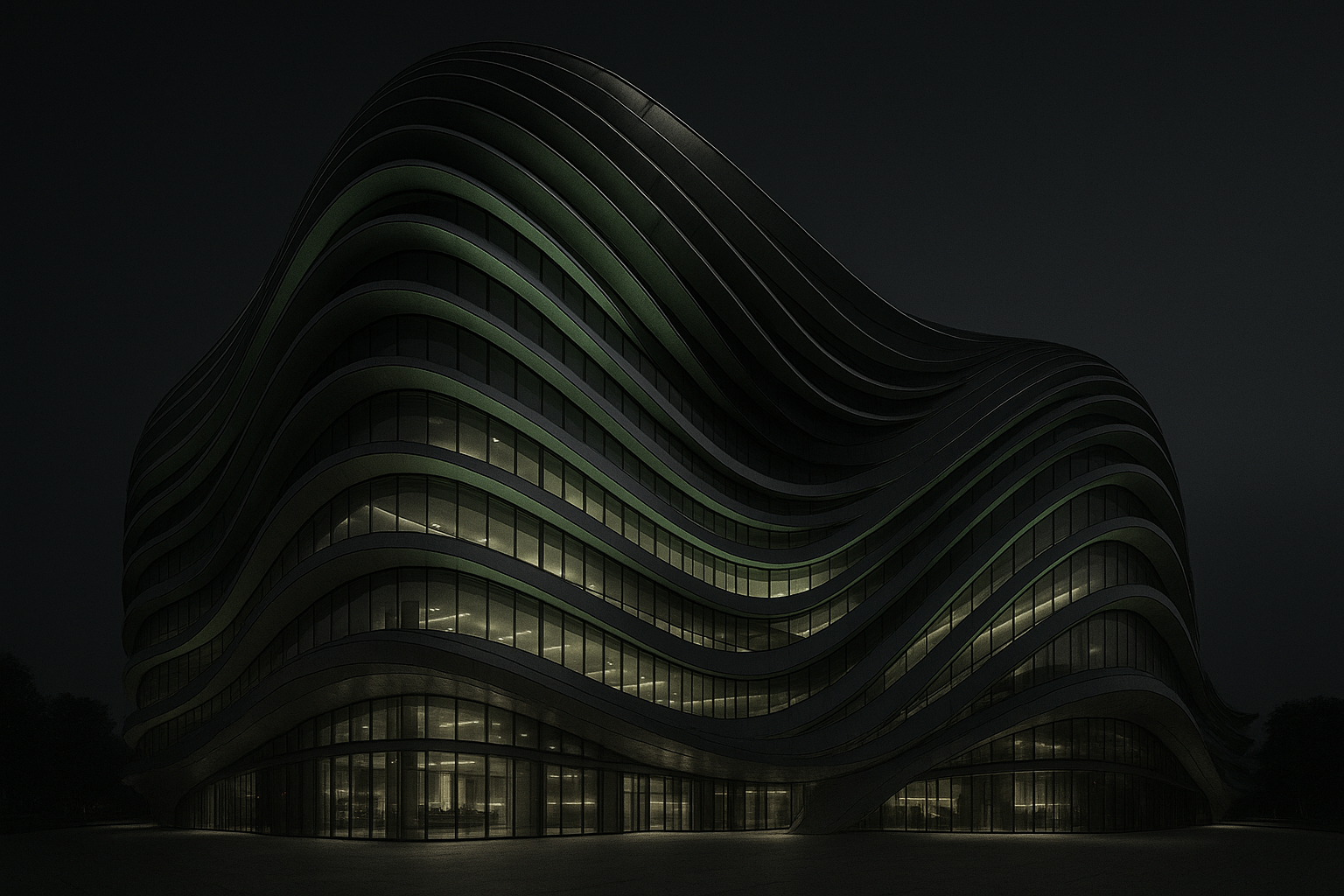

From mall entrances and train station canopies to sculpted wall features, curved architectural panels are common sights. These forms may appear effortless, but they often result from the careful bending of aluminum sheets or extrusions. Behind these shapes is a balance of engineering accuracy and smart material selection with aluminum leading the way.

Why Curved Panels Make Spaces Feel Grand

Design That Moves With You

Curved lines feel natural. In public buildings, they help guide foot traffic, soften hard edges, and create openness in crowded spaces. Architects use bent aluminum panels to realize flowing forms that give character and movement to a structure. The material makes these shapes possible, but it’s the architectural vision that gives them meaning.

Aluminum: The Flexible Armor for Big Buildings

Lightweight. Corrosion-Resistant. Shapeable.

Aluminum combines low weight with strong performance and resistance to corrosion, making it well-suited for cladding and canopy structures in buildings exposed to weather and pollution. Airports, train stations, and similar environments benefit from these qualities. However, only certain aluminum alloys are suitable for bending. 5005, 5052, and 6061 in softer tempers like H32 are commonly used due to their ability to form without cracking. The level of corrosion protection depends on the alloy and finish, with treatments like anodizing and powder coating providing greater durability in harsh conditions.

Paneling Systems That Bend the Rules

From Flat Sheets to Flowing Forms

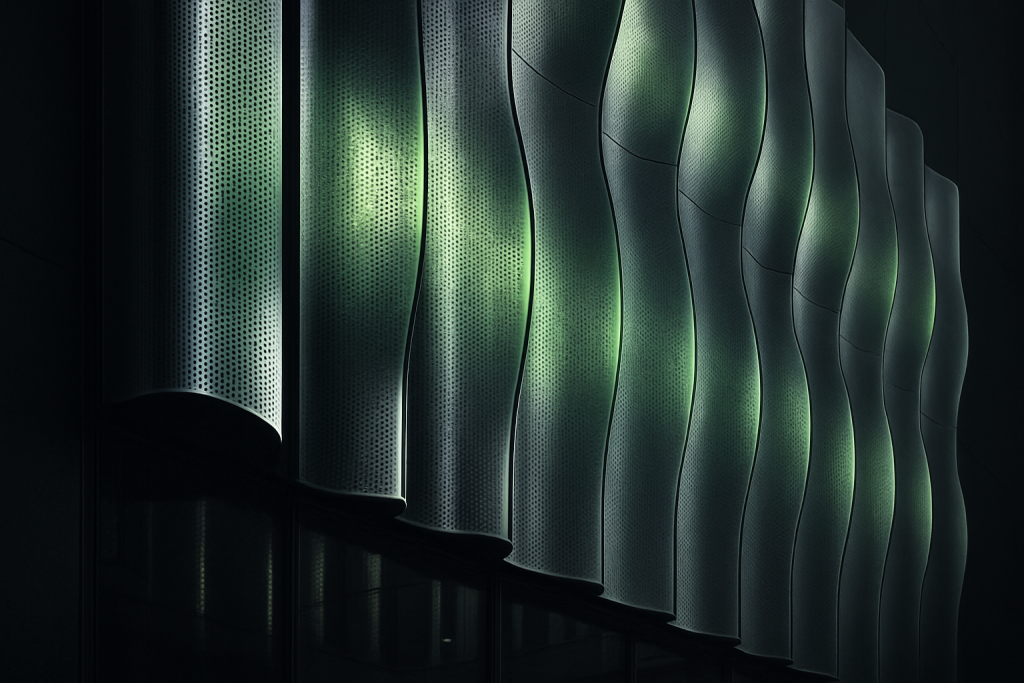

Modern forming methods make a broad range of architectural shapes possible. Techniques include:

- 3-roll and 4-roll CNC bending (commonly used for extruded profiles)

- Stretch forming (more suitable for large panel surfaces)

- Press braking

- Incremental bending

- Each method is best suited to particular shapes and project scales. Roll bending works well for long, straight-line profiles. Stretch forming is more often used when designers need smooth, wide curves across panels.

Built for Transit, Trusted for Retail

Where You’ll See These Panels in Action

Curved aluminum panels serve a structural and visual role in many high-use locations. You’ll find them in:

- Roofs, soffits, and façades of train stations

- Entry canopies and interior cladding in malls

- Rooflines and walkways in airport terminals

- Outer walls of cultural venues and stadiums

These projects often use aluminum sheets alongside composite panels like Alucobond. Subframe systems provide support, helping the panels meet both performance and appearance requirements.

How Aluminum Panels Are Made to Fit Perfectly

From CAD to Curvature

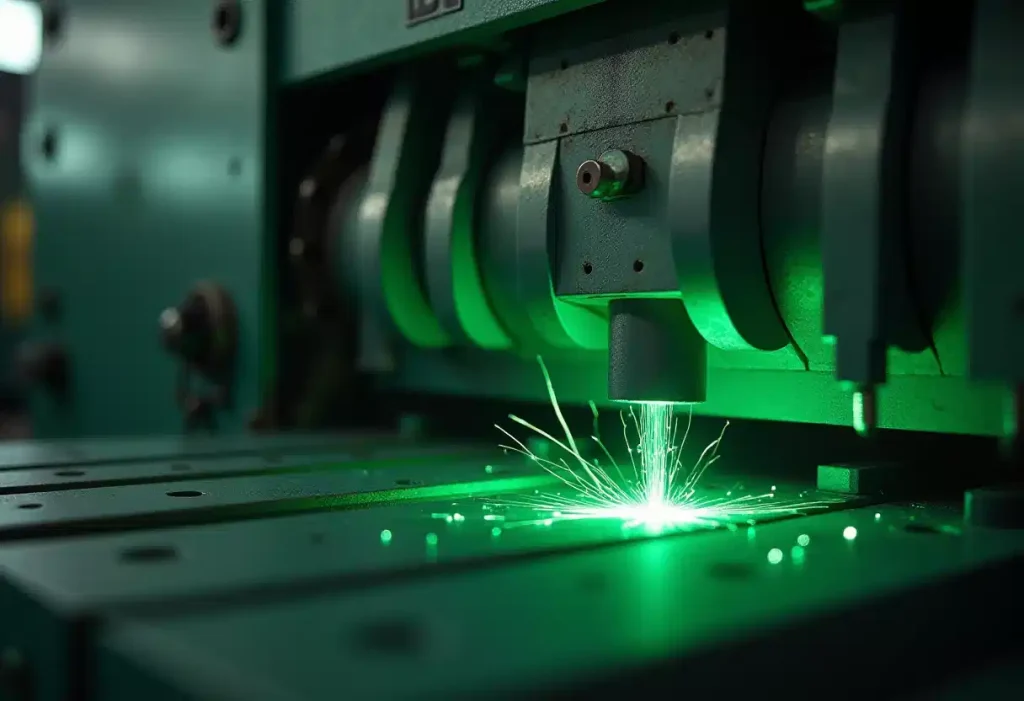

The design and forming process begins with a digital model. Engineers create 3D CAD files that define the required shapes and tolerances. The process includes:

- Converting CAD files into machine instructions

- Cutting sheets with CNC routers or lasers

- Bending with the most suitable machine for the curve

- Verifying dimensions against tolerances

- Applying finishes such as anodizing or powder coating

- Installing panels using custom mounting systems

Panels are typically formed offsite in sections that allow for simpler transport and quicker installation.

Engineering Meets Aesthetics

Curves That Cool, Shield, and Shine

Curved aluminum panels provide both appearance and performance. Their shapes can:

- Help water and debris run off quickly

- Allow air to flow behind ventilated façades

- Reduce unwanted heat buildup, depending on how the building is oriented

These benefits come from how the curved panels are integrated into the full system. The results depend on design decisions, spacing, finishes, and how the panels are mounted.

Sustainability on a Grand Scale

Built Green with Every Bend

Aluminum offers long life and recyclability. It is:

- Recyclable again and again without losing strength

- Reliable even in rough environments

- Acceptable under many green building programs such as LEED and BREEAM

Project teams looking to reduce impact often request aluminum with a high recycled content. This choice lowers the overall carbon footprint of the structure.

Curved Aluminum: Quietly Redefining the Cityscape

Take a closer look next time you’re under an arched canopy or along a sculpted building edge. These curves probably began as flat aluminum pieces, bent carefully to match the structure’s design. Aluminum forms cleanly, stays strong, and stands up to the elements, making it a dependable solution for architectural curves.

As buildings shift toward smoother lines and better use of materials, aluminum continues to support both structure and design. It helps realize complex forms and maintain long-term durability in public and commercial spaces.

Inductaflex helps bring these curves to life.