From Flatbed to Festival in Hours

Modern festivals, trade shows, and pop-up events all depend on structures that are quick to assemble and strong enough to handle a full production setup. Bent aluminum tubing makes this possible. It supports everything from stage platforms and AV equipment to booth frames and signage. Its lightweight nature and adaptability make it suitable for repeat use in tough, changing conditions.

Why Bent Aluminum Owns the Spotlight

The Performer Behind the Performance

Aluminum is commonly used in mobile event structures for good reason. It’s light but strong, easy to shape, and resists corrosion in outdoor conditions. Since it’s non-magnetic, it’s safe to use near speakers, video walls, and sensitive gear. Common alloys such as 6061 and 6082 strike a balance between strength and formability, though they are usually bent before being heat-treated to the T6 temper to maintain flexibility during forming.

Truss Systems: The Skeleton of the Show

Modular Frames that Snap, Stack, and Soar

Aluminum tubing forms the backbone of modular truss systems. These systems are built to connect easily and pack down efficiently. You’ll find bent tubes used in:

- Curved lighting trusses

- Arched entrances

- Domed and pitched roof structures

- Vertical towers for screens and speakers

Crews can swap, link, or stack truss pieces based on the venue’s needs. This setup reduces time spent on installation and saves space during transport.

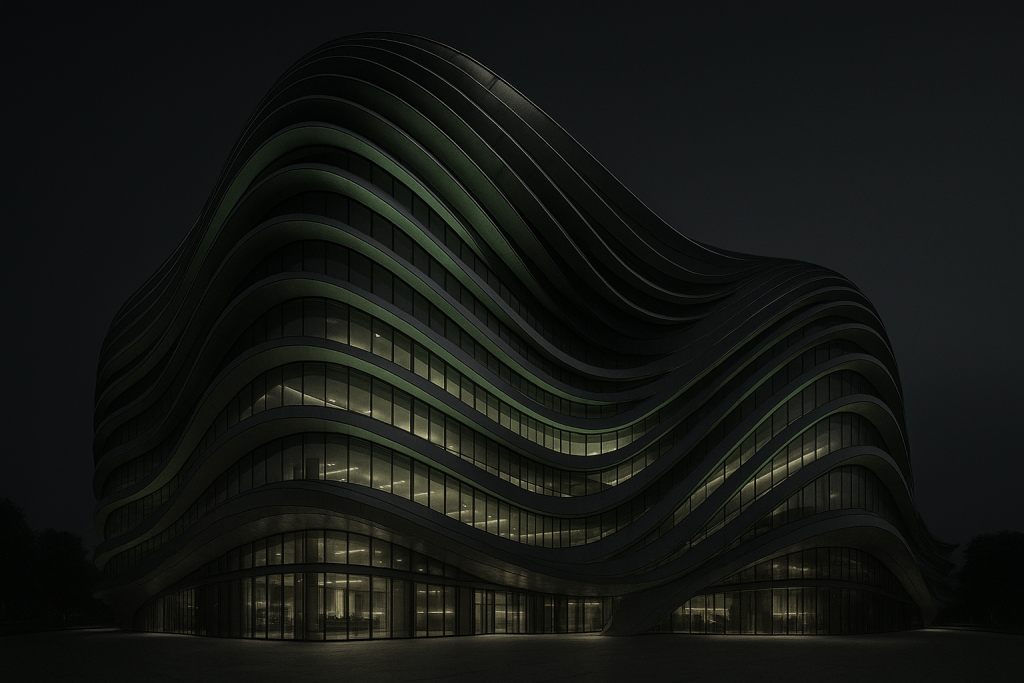

Bending for Boldness: Curves That Command Attention

Design That’s Built to Travel

Curved aluminum tubing serves more than one role. It provides structural support while also making a visual impact. Arches and sweeping lines define entrances, frame stages, or hold circular lighting rigs. CNC bending delivers consistent curves but keeping them protected in transit still requires good packaging and handling.

Strength That Moves

Light to Lift, Tough to Topple

Aluminum’s strength-to-weight ratio allows large spans to be built without extra supports, which simplifies installation and keeps the stage open and accessible. True load-bearing ability, however, comes from combining the right material size, wall thickness, joint quality, and support layout. Elements that must be engineered and tested together.

Fast Assembly, Seamless Logistics

Speed Wins on Show Day

Tight show schedules demand speed. Lightweight bent aluminum tubing makes it easier to carry, lift, and position parts. Its modular design speeds up connections. Crews benefit from systems that stack, nest, or fold flat, which helps them pack trucks quickly and cut down setup time on-site.

Where You’ve Seen It Before

From Coachella to Corporate Launches

Bent aluminum tubing is common across different events. Examples include:

- Main stages at outdoor music festivals

- Booth structures at trade shows

- Art pavilions and pop-up installations

- Touring setups for concerts and brand activations

These structures travel easily and assemble quickly, making them a favorite for event teams working across multiple venues.

Future-Ready, Event-Tested

Sustainable, Scalable, and Show-Stopping

Aluminum truss systems are built to last. When crews handle and store them properly, these systems can perform at event after event. They resist rust, maintain their shape, and clean easily. Event producers value aluminum for its durability and low waste output. At the end of its service life, aluminum is recyclable but structural tubing may need sorting or cleaning before it’s accepted at recycling facilities.

Conclusion

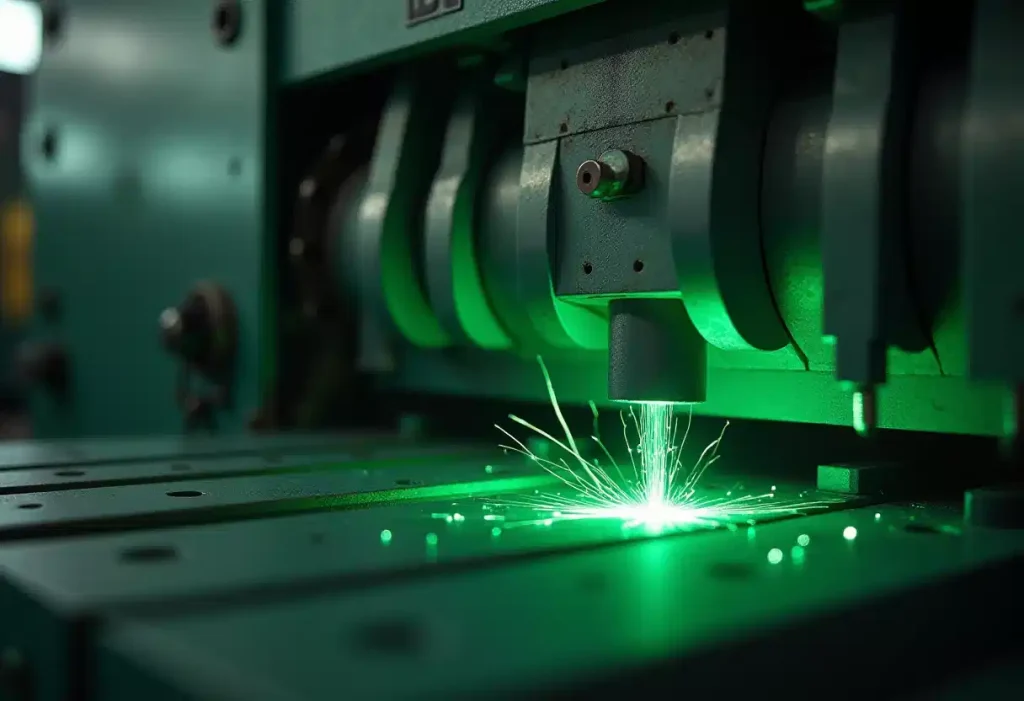

Design in Motion, Powered by Precision Bending

Bent aluminum tubing has become a core material in modern event production. It holds lighting, defines layouts, and supports large installations. However, its use must be supported by proper engineering and care. Each piece is made to fit a specific purpose and simplify on-site work.

As the industry focuses more on speed and reuse, aluminum remains a go-to material for mobile setups. Its mix of strength, weight, and shape flexibility makes it a practical standard across touring, exhibition, and live event environments.

Inductaflex helps create the bends that keep events moving one frame at a time.