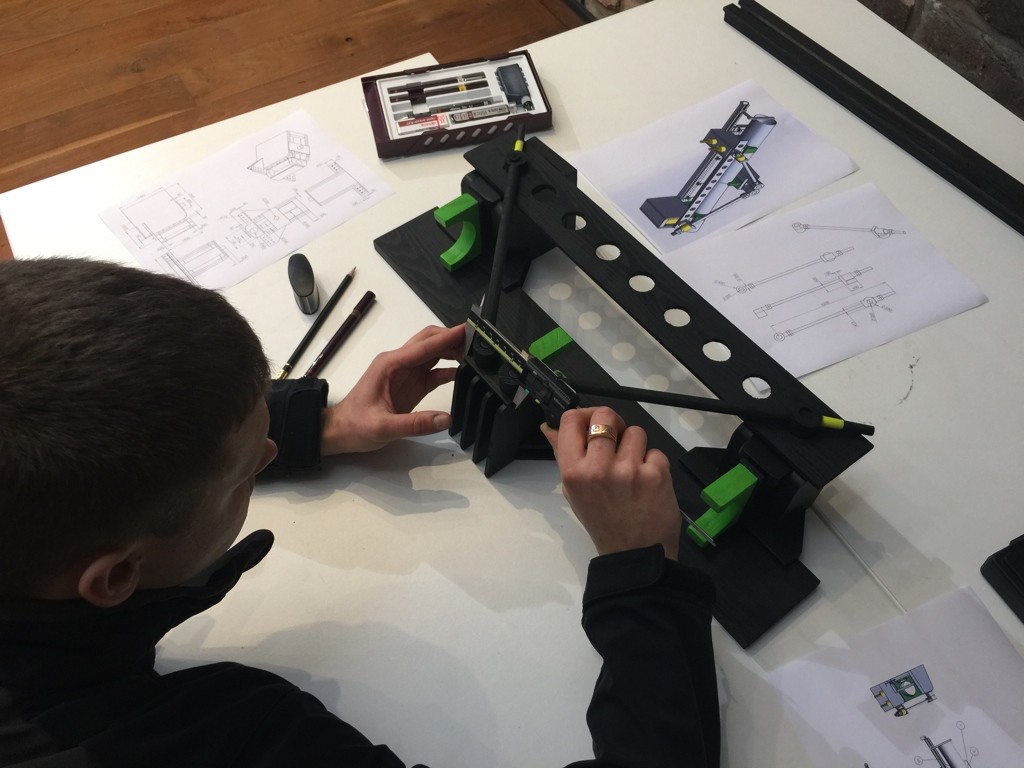

When Inductaflex develops new machines, we not only provide a 3D simulation but also supply a 3D printed scale model. This helps clients visualize the design before giving final approval.

These models often include movable parts and accurately simulate the bending environment. We place them on a scale layout of the site for better context.

This process frequently reveals improvements to the machine or surrounding workflow. For example, it can expose handling issues, which often affect cycle time – especially when working with large components requiring two, three, or even four-point slinging.

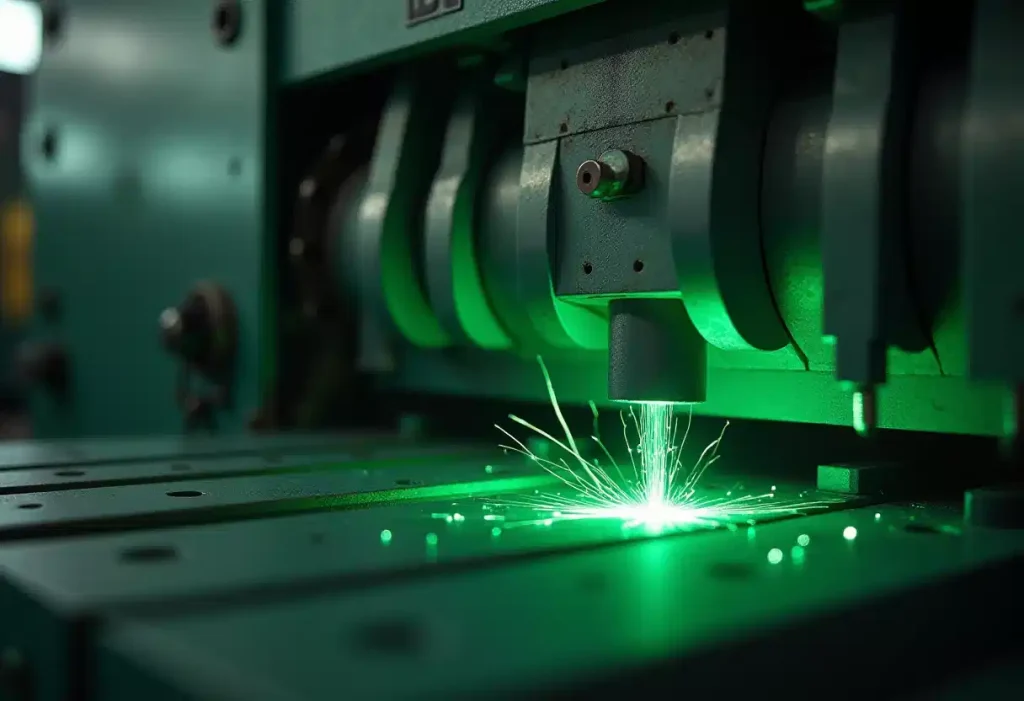

Discover how our 3D printing capabilities bring custom metal bending machines to life. Explore more innovations and follow us on YouTube for the latest updates.