Aluminum bending machines are becoming more automated. For these systems to function well, they need to make fast decisions without relying on external servers. This is where edge computing comes in. Processing power sits directly in the machine, helping it respond quickly and work more accurately. For manufacturers building automated lines, local processing plays a major role in keeping operations smooth and responsive.

This article explains how edge computing fits into aluminum bending and how it supports real-time production.

What is Edge Computing in Manufacturing?

Edge computing means that machines process data right where it’s created. Instead of sending all information to a remote server, the machine handles it immediately and locally.

It works alongside cloud systems but handles tasks that can’t wait. When real-time reaction is needed, edge computing avoids delays. It also reduces network load and keeps operations running during network disruptions. In aluminum bending, quick decisions help prevent errors and wasted time.

Benefits for CNC Bending Operations

Adding edge computing brings clear benefits to bending machines.

Real-Time Feedback Loops

Machines can respond to material changes in milliseconds, which is fast enough to manage variations in feed rate, roller position, or springback effectively. They adjust feed rates, roller movement, or pressure on the spot. This kind of responsiveness helps avoid problems caused by springback or shifting alignment.

Improved Uptime

Built-in tools track performance and detect wear or faults early. Operators can respond before anything breaks down, which keeps production on track.

Data Privacy

Production data stays inside the facility. While local processing keeps data in-house and improves control, full compliance with aerospace or defense regulations also requires secure hardware, encryption, and user access controls.

Power Use

Machines shift between full and low-power states depending on their workload. This helps lower energy use without slowing down production.

Use Cases in Bending Cells

Edge computing supports practical tasks inside aluminum bending systems.

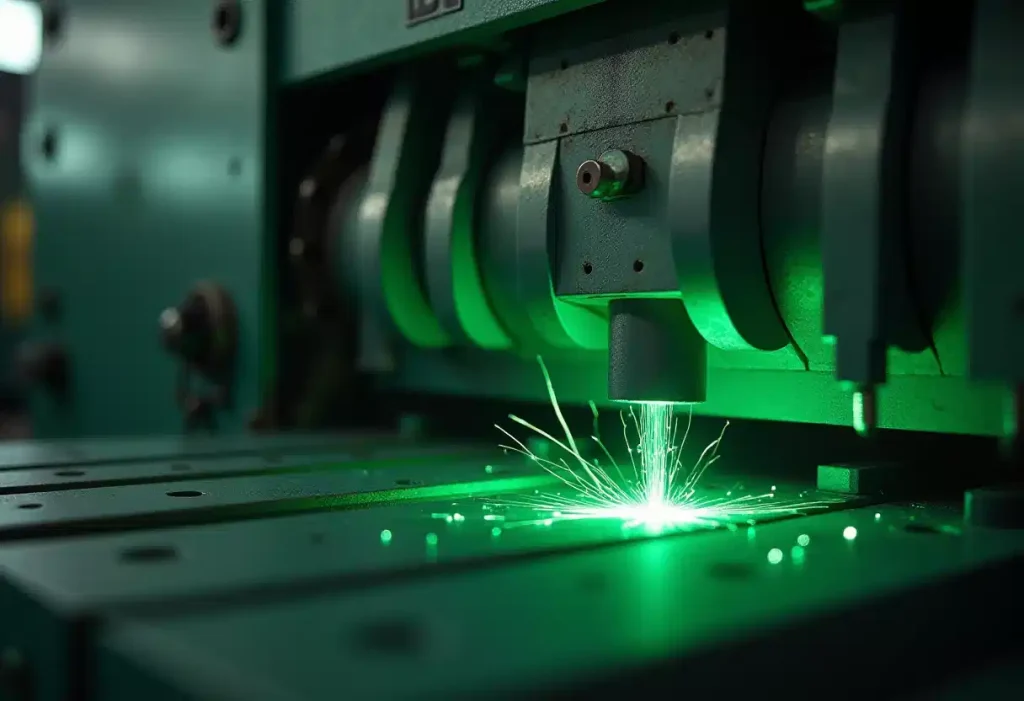

Error Correction While Running

Sensors pick up springback or slip during bending. The system reacts while the cycle is still running, which helps maintain precision with no interruption.

Smart Tooling

Tooling sensors send real-time data to the machine’s local processor. That data helps control quality and keeps tools from wearing out too quickly. To be effective, smart tooling relies on accurate calibration and sensor maintenance, otherwise, data quality can degrade over time.

Vision Systems

Cameras compare the finished part to the digital design. Because this happens inside the machine, the check is fast and doesn’t need remote analysis.

Machine-to-Machine Communication

Machines inside a bending cell share information directly with each other. They coordinate operations without using a central server.

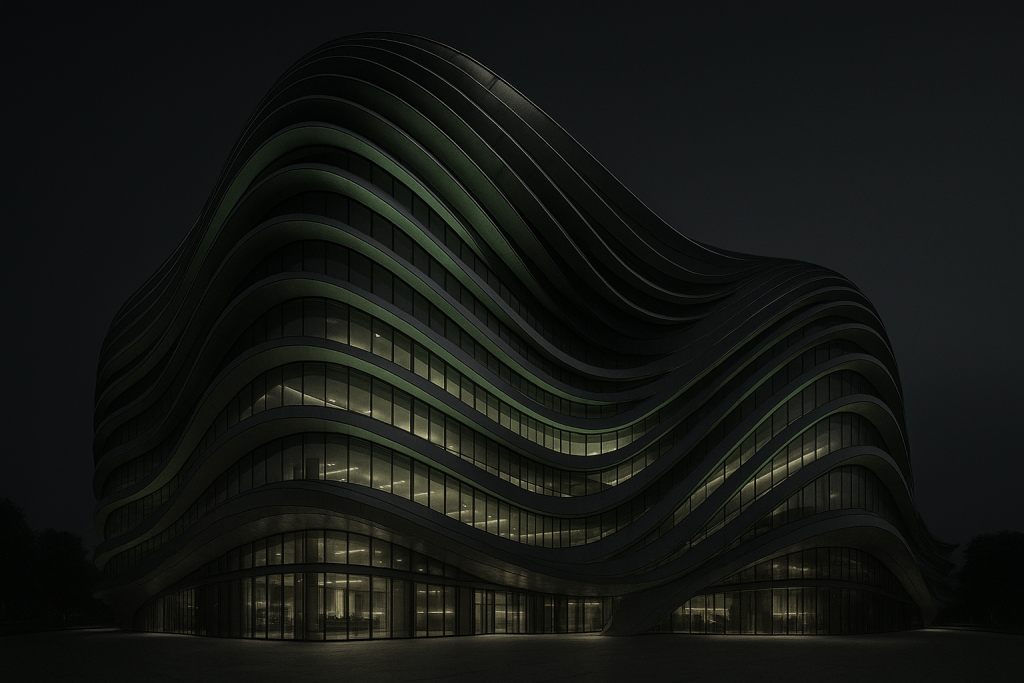

System Architecture: How It Fits

The setup behind edge computing is designed for shop-floor conditions.

Machines use common communication standards like OPC-UA or MQTT to stay connected to factory systems. Controllers are built into CNC or PLC hardware. Some advanced CNC and PLC systems now include processors capable of handling sensor fusion or simple AI logic, though this is more common in newer or specialized edge setups.

These setups also support secure updates and report data to both technical teams and production staff. Edge architecture should also account for environmental factors like dust, heat, and vibration, which can affect performance in heavy-duty bending environments.

Industry Implications

Edge computing supports fully automated bending. Machines stay active around the clock without constant human oversight. Edge systems allow most bending operations to continue even if internet access is lost, although some remote features like updates or licensing checks may be paused.

This setup also works well in off-site or mobile units. Systems installed in containers or at temporary job sites can operate independently, without relying on cloud access.

It also speeds up process changes. Because the machine handles data on-site, engineers and operators can review results immediately and make fast decisions.

Smarter Cells Need Smarter Infrastructure

Automation is changing how aluminum bending works. Modern systems must react instantly to material shifts and operational feedback. Edge computing helps make that possible by placing decision-making directly in the equipment.

Faster adjustments, fewer interruptions, and more control mean better results across the board. Production stays consistent, and teams can correct problems as they happen.

Inductaflex systems are built with local processing tools inside, so your bending equipment is ready to meet today’s challenges, wherever it runs.