As aluminum profiles become more complex, so do the challenges in bending them. Simple programs and manual adjustments no longer keep up with the precision and speed that today’s industries need. That’s why more manufacturers are using smarter CAM/CAD software and systems.

Modern CAM does more than move a machine from one point to another. It reads complicated shapes, accounts for how materials behave, and adjusts toolpaths to get better results with less waste and rework. This article breaks down how CAM helps make bending faster, more accurate, and easier to manage.

How Smart CAM Optimizes Toolpaths

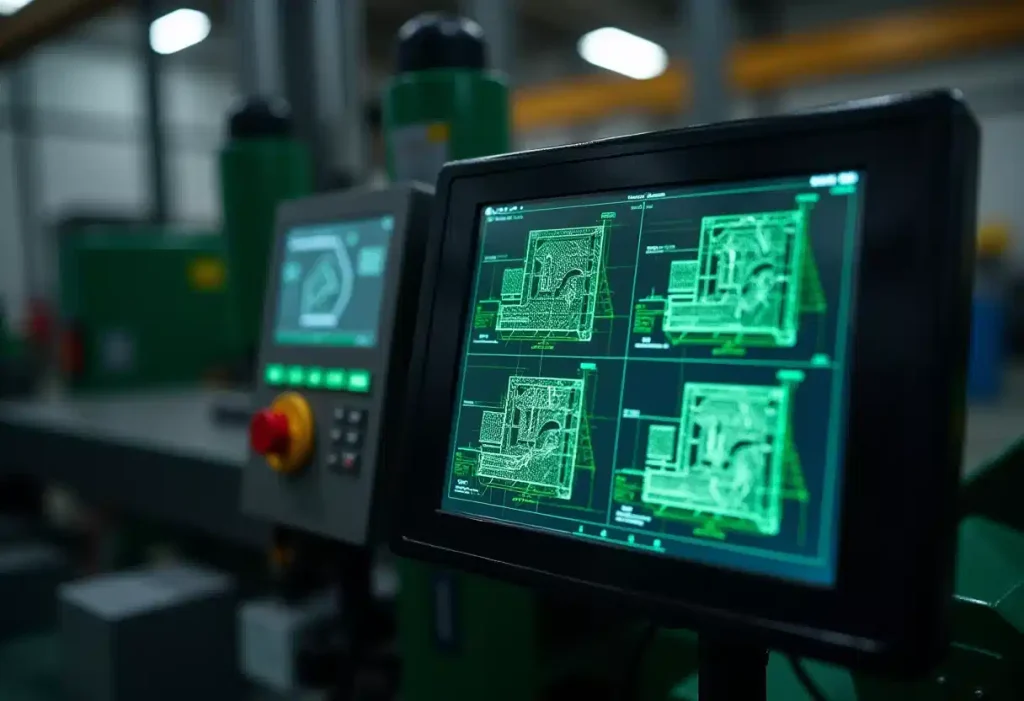

Before a machine can bend a profile properly, it needs to understand the shape.

Geometric Recognition

Today’s CAM software reads cross-sections, bend radii, and profile shapes directly from design files. This reduces the need for programmers to define every detail manually. It speeds up setup and lowers the risk of early mistakes.

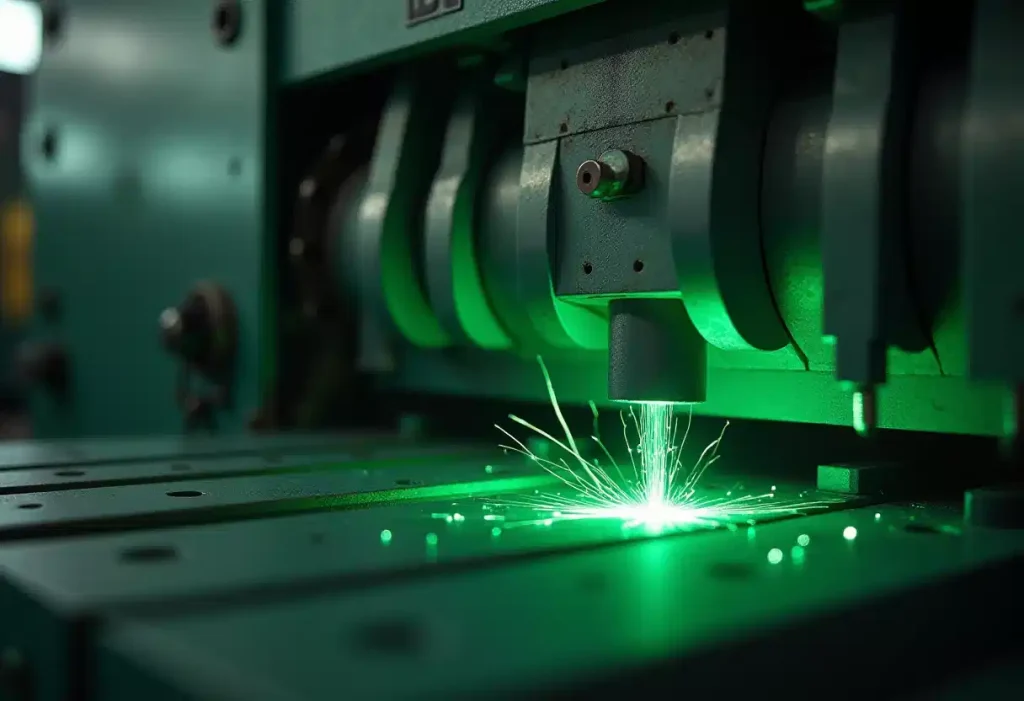

Predictive Adjustments

CAM systems can apply corrections for springback, stretch, and hardening based on material data, test results, or machine calibration. These values are usually entered by engineers or drawn from past successful bends. These built-in corrections help deliver accurate results with fewer test runs and less material waste.

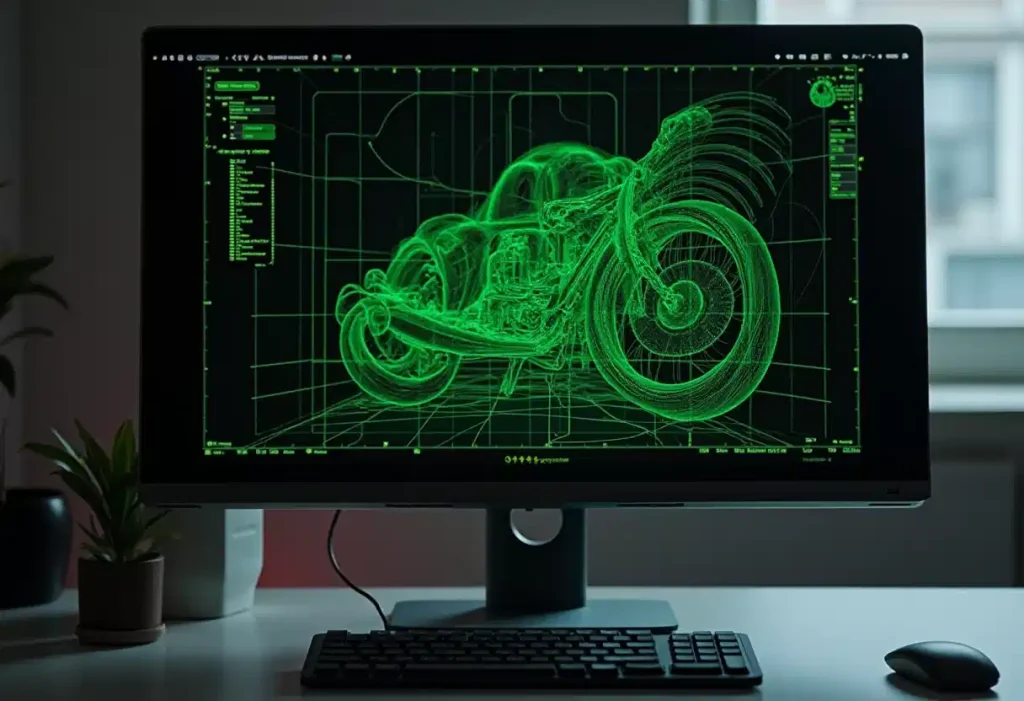

Coordinating Multi-Axis Movement

Bending machines often rotate, tilt, and feed material all at once. Planning those movements manually takes time and risks errors.

Efficiency and Accuracy Benefits

Smart CAM brings several key benefits to the shop floor. It helps cut waste, reduce errors, and make tool life last longer.

Fewer Fixes

Carefully planned toolpaths lower the chances of bends being too shallow or too sharp. This reduces the need for adjustments and rework.

Shorter Production Times

Machines move more efficiently when the software eliminates unnecessary steps and idle movements. This shortens the overall production cycle and helps the shop turn around parts faster.

Less Tool Wear

Smooth transitions and balanced loads reduce strain on tooling. Over time, this slows down wear and keeps dies and rollers in better condition.

Technology in Practice

These improvements aren’t just theoretical. Shops are already using these features to get more consistent results.

Learning from Past Bends

A few CAM environments store job history or toolpath data, which can help programmers fine-tune future bends. However, this feature is more common in advanced platforms that combine CAM with part libraries or data-driven optimization tools. This improves repeatability, especially for short-run or custom parts.

Real-Time Corrections

Some advanced bending machines are equipped with sensors that track position, force, or deflection during bending. These sensors send data to a controller, which may then adjust motion parameters in real time. This type of correction typically occurs through the machine’s control system, rather than standard CAM software.

Previewing Before Production

CAM software can now display a 3D simulation of the bending process. Operators use these previews to spot problems before running parts. They can check clearances, movement limits, and potential collisions upfront, instead of waiting for errors on the shop floor.

Best Practices for Implementing Smart CAM

You don’t have to change everything at once to benefit from smarter software. Some small updates to your workflow can make a big difference.

Keep Software Up to Date

Installing updates gives access to new tools, improved functions, and better file support. This helps the system run smoothly and stay compatible with the latest formats.

Use Feature-Based Tools

When programmers apply feature recognition tools, CAM software can quickly adjust to design changes. This saves time on revisions and lowers the chance of manual errors.

Involve Your Team

Let designers and machine operators review toolpaths together before production. This keeps everyone on the same page and makes it easier to catch issues early.

Conclusion

Smart CAM is changing the way we bend aluminum profiles. Instead of relying only on operator skill and manual planning, shops now use software that reads the part, accounts for material behavior, and organizes each machine movement clearly and predictably.

These systems help reduce mistakes, improve repeatability, and shorten turnaround times. They also make it easier to handle jobs with tighter tolerances and more demanding materials. When bending operations stay consistent and accurate, the entire production process benefits.

This change isn’t just about adding automation. It’s about giving bending teams more control over each part they make. With the right CAM system, operators can get repeatable results, even with complex designs and tough materials.

Contact Inductaflex for more support.