Aluminum bending projects are becoming more complex. Shapes are harder to produce, tolerances are tighter, and mistakes cost more time and material. To meet these demands, manufacturers now use digital twins, virtual models that reflect the behavior of machines and bending processes. These tools help teams test, adjust, and troubleshoot by simulating real-world machine behavior, though outcomes depend on how well the model is tuned to actual process data.

This article explains how digital twins are applied in aluminum bending and why they’re becoming a valuable tool on the shop floor.

What Is a Digital Twin?

A digital twin is a computer-based model that mirrors a physical machine or process. It uses data from sensors, software, and operators to show what’s happening on the production line.

Engineers can use the model to monitor machines and simulate different bending sequences. These models often update in near real-time, depending on the speed of data transmission and system integration.

Benefits in Aluminum Bending Applications

Digital twins offer several practical uses in bending operations.

Simulate First, Then Run

Engineers can run a full bending sequence on the digital model before touching a part. This includes checking tool paths, roller pressure, and how the material might respond. Simulating beforehand helps prevent mistakes during setup.

Identify Setup Issues Early

Virtual models can reveal tooling misalignments, machine collisions, or incorrect programming. Spotting these issues ahead of time helps avoid damage and keeps production moving smoothly.

Monitor Machine Health

Digital twins track component behavior over time. Operators can review pressure changes, roller wear, or slowing cycle times, which may suggest the need for maintenance.

Test Material Reactions

When working with different alloys or wall thicknesses, the system lets engineers try out changes and see how the material reacts before starting a real bend.

Key Technologies Enabling Digital Twins

Several tools work together to make digital twins function well in bending lines.

Machine Sensors

Sensors installed on parts like rollers, drive motors, and moving arms gather data on position, speed, and load. That data goes directly into the model for tracking and comparison.

Simulation-Ready Software

CAM software such as Siemens NX and Dassault Systèmes tools offer process simulation features. Fusion 360 may support simpler modeling but it is limited for bending-specific simulations.

Predictive Tools

Basic AI and rule-based programs help track wear and suggest when to take action. While full AI twins are rare in bending, some early systems are starting to appear in newer equipment.

Communication Standards

Protocols like OPC-UA and MQTT help machines and software exchange information. These tools keep the digital model in sync with physical operations. Standards like OPC-UA help industrial machines and software communicate. MQTT may be used for lightweight sensor networks, but full integration depends on the control system’s capabilities.

Use Cases in the Field

Each industry uses digital twins to solve specific bending challenges.

Aerospace

Digital twins help test bending sequences for frames and brackets that need high accuracy. These systems also show how parts respond to changes in temperature or vibration.

Automotive

Engineers use models to adjust for springback in high-strength materials. In some setups, the digital twin can suggest tool path adjustments for springback compensation, though closed-loop feedback still requires specific controller and sensor integration.

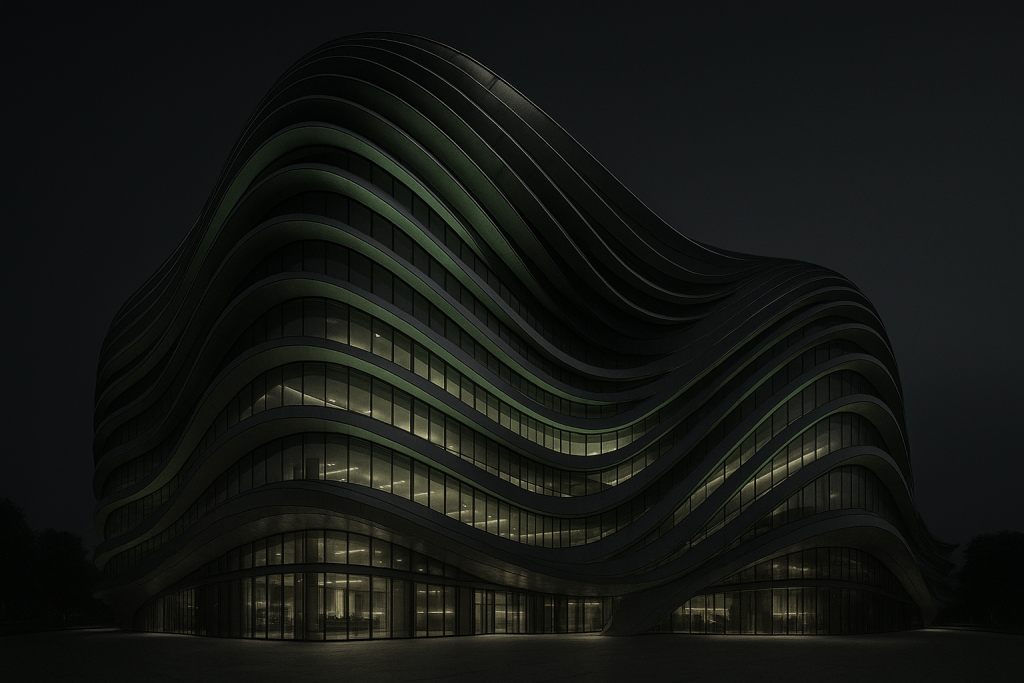

Architecture

When forming curved parts for cladding or façades, digital twins help confirm shape accuracy. They also help identify profile changes that may affect appearance or fit.

Job Shops

Shops handling low-volume or one-off jobs use digital twins to reduce setup time. Instead of trial and error, the machine starts with a validated plan.

Implementation Considerations

Applying digital twin systems requires preparation. Here are some key factors to review:

Machine Requirements

Your bending machine must allow data to move in both directions. Some older models may need upgrades or external modules to support this function. Some machines may only support one-way data logging, which limits real-time simulation or corrective actions.

Software Compatibility

Your modeling program must link with the rest of your tools. CAM, MES, or ERP systems should accept data from the twin and send instructions back when needed.

Data Protection

Bending models may contain proprietary designs or process details. Keep them secure with restricted access, regular updates, and secure networks.

Operator Training

Operators must know how to read the model and understand how it compares to real bending behavior. This helps prevent confusion when the material responds differently than expected.

Smarter Decisions Before Metal Moves

Digital twins give engineers and operators more control over bending. Simulations help fine-tune each job before any material is touched. With this kind of preparation, teams can cut down on wasted parts, reduce downtime, and achieve better accuracy on the first try.

More companies are seeing improvements when using digital models alongside their production systems. Setup times can improve, and errors may decrease when the digital twin is accurately linked to production data and properly maintained. These tools aren’t just useful, they’re quickly becoming a regular part of how bending lines are built and managed.

Inductaflex machines support real-time data links, giving your team the control needed to make each bend count.